Hot dip galvanizing is a method of protecting steel from corrosion by dipping it in a bath of molten zinc.…

Projects we are proud to have been involved in…

Ropeworks

The Ropeworks is a multi-phase housing development in Leith, Edinburgh which sees…

Galvanizing is Tough – British Antarctic Survey

Galvanizing has an abrasion resistance up to ten times better than organic…

Belfast Rise

Standing at 37.5m high, the Belfast Rise is Northern Ireland’s tallest public…

Connor’s Court, Brighton

Connor’s Court is a multi use games area in the south coast…

Commonwealth Games

Glasgow enjoyed a sporting party for two weeks in the summer of…

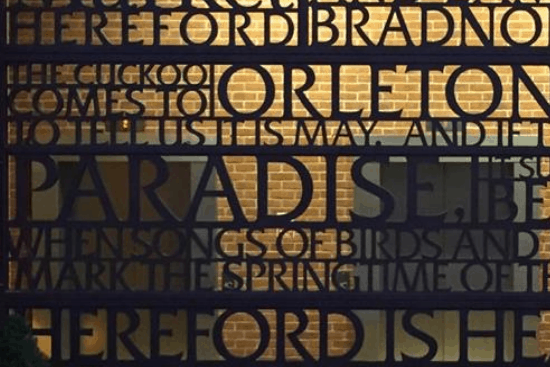

Old Market Hereford

The Old Market Hereford is a new £90m shopping, dining and entertaining…

Roseisle Distillery

Named Scottish Building Project of the year, Roseisle Distillery is the first…

The Edinburgh Military Tattoo

220,000 visitors to Edinburgh Tattoo in 2011 would not have realised the…

Latest News

Contemporary Housing Developments

Contemporary Housing Developments Are you looking for a coating that gives you unrivalled protection along with the selection of any…

How to Reduce the cost of Galvanizing

How to – Reduce the cost of Galvanizing At Highland, we always want to provide the best coating finish possible…